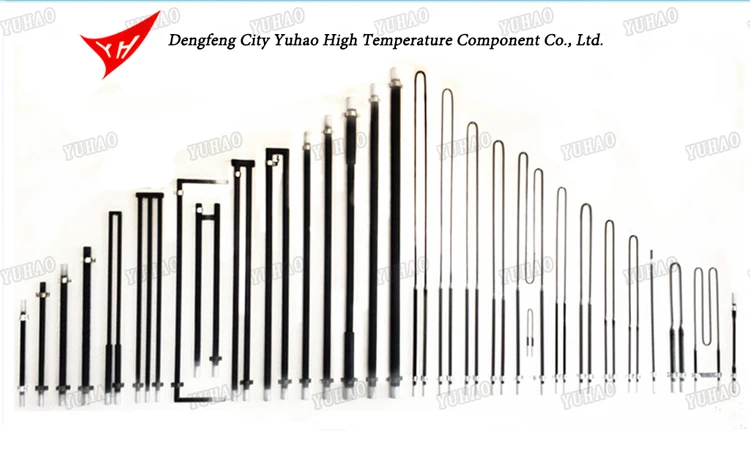

YUHAO high purity 1800 degree u shape mosi2 heating elements for dental furnace

Description

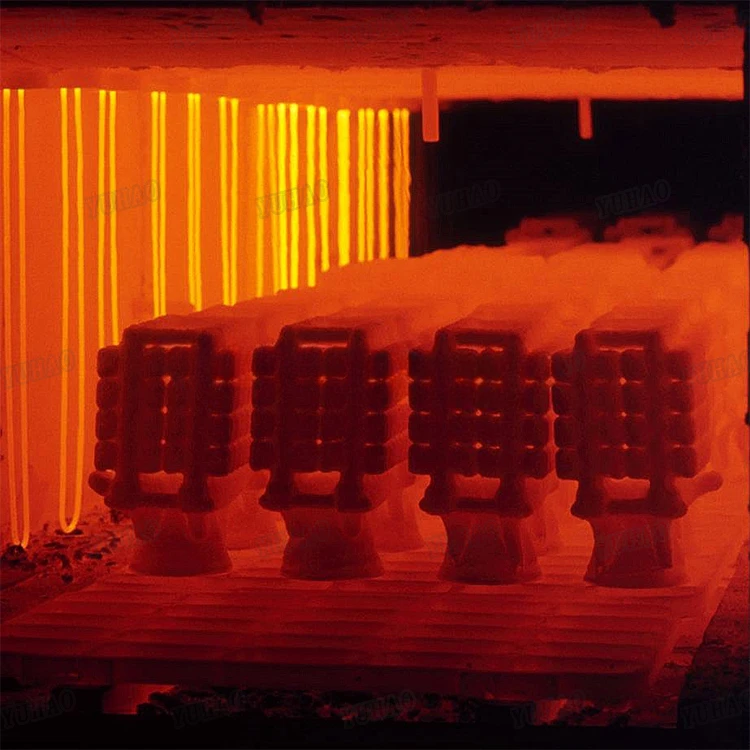

YUHAO High Purity 1800°C U-Shape MoSi2 (Molybdenum Disilicide) heating elements are high-performance components designed for use in dental furnaces. These heating elements are specifically engineered to provide consistent, high-temperature heating, ideal for processes such as sintering, firing ceramics, and other dental applications that require precise temperature control. Made with high-purity MoSi2, these elements ensure optimal performance and long-lasting durability.

Features:

- High Purity MoSi2: Manufactured from high-purity molybdenum disilicide (MoSi2), known for its excellent high-temperature resistance, stability, and corrosion resistance.

- Temperature Rating: Capable of reaching temperatures up to 1800°C, making them suitable for various high-temperature dental applications such as sintering zirconia, ceramics, and other dental materials.

- U-Shape Design: The U-shape configuration allows for efficient heating distribution, ensuring uniform temperature across the furnace for precise results.

- Durability and Longevity: MoSi2 is known for its ability to withstand prolonged high temperatures, ensuring a longer lifespan and consistent performance even under intensive use.

Benefits:

- High-Temperature Performance: Withstand temperatures up to 1800°C, ensuring reliable heating for dental furnaces and laboratory applications.

- Efficient Heating: U-shape design helps achieve uniform and efficient heating, which is essential for accurate sintering and firing processes.

- Long-Lasting Durability: High-purity MoSi2 provides superior resistance to oxidation and thermal degradation, ensuring a longer operational life.

- Stable Performance: Designed to maintain stable, consistent heating, crucial for achieving high-quality dental restorations.

1.U type mosi2 heating element is a kind of resistance heating element basically made of high pure Molybdenum Disilicide.

2. In oxidizing atmosphere, its Max temperature can reach 1800 deg.C, and its applicable temperature is 500~1700 deg.C.

3. It can be widely used in such applications as sintering and heating treating of ceramic, magnet ,glass, metallurgy ,refractory, ect.

Chemistry Property

Under high temperature, MoSi2 heating element will form one SiO2 protective film on the surface, which prevents the element from oxidizing continuously.

The Influence of Different Atmospheres

|

Atmosphere

|

The Max Using Temperature of Element

|

||||||

|

1700 Grade

|

1800 Grade

|

||||||

|

NO2, CO2, O2, Air

|

1700 °C

|

1800 °C

|

|||||

|

He, Ar, Ne

|

1650 °C

|

1750 °C

|

|||||

|

SO2

|

1600°C

|

1700°C

|

|||||

|

CO, H2

|

1500 °C

|

1600 °C

|

|||||

|

Wet H2

|

1400°C

|

1500°C

|

|||||

|

Dry H2

|

1350°C

|

1450°C

|

|||||

Accessories

Packing Details : Be packed in standard export wooden boxes, outer wooden boxes and inner foam sponges.

Delivery Details : 5 working days after order of Mosi2 heating elements.

1. Special logistics packaging

2. Suitable carton size

3. Shock bubble film

4. Professional placement

5. Professional shock

6. Complete package

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5 working days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: